Are You A Vanguard? Applications Now Open

This is your first of three free stories this month. Become a free or sustaining member to read unlimited articles, webinars and ebooks.

Become A MemberHe might appear mild-mannered, what with his collared shirts, thin-rimmed spectacles and white hair. But John Workman is sort of a superhero.

A pilot who owns World War II-era planes, Workman leads flyover shows that awe citizens in his town of Muskegon, Mich., on the Lake Michigan coast. He volunteers to fly sick children in west Michigan across the country, for free, so they can get life-saving medical treatment. And, in dim rooms shot through with sparks, employees of the company he co-owns work with molten steel at temperatures of 2,900 degrees.

This last bit might be Workman’s most impressive feat: He is a 21st-century American manufacturer.

With gorgeous beaches and a tradition of thriving industry (its timber rebuilt Chicago after the 1871 fire), Muskegon is both a place of play and a place of work. But about a decade ago, the city considered cutting its losses and reorienting itself entirely for tourists. Muskegon’s community developers came together to debate the point, because it didn’t look like manufacturing jobs would ever come back to the United States, let alone the Rust Belt. It was tempting to see Muskegon’s history of making things, from beds to heaters to porcelain enamel, as just that — history.

But they didn’t do it. Muskegon’s leaders instead decided to back manufacturing by investing in infrastructure: Roads, water, sewers. “Then, when manufacturing started coming back, we were ready,” said Cindy Larsen, president of the Muskegon Lakeshore Chamber of Commerce.

Growing up in Muskegon, Workman saw it all up close. His father, Harold, worked as human resource director for two local companies: Campbell, Wyant & Cannon and Dresser Industries. Harold is credited with bringing 7,200 workers from the South to Muskegon in the 1940s, when the city’s iron foundries brimmed with business from the auto industry and military. Harold also helped found the Muskegon Area Labor Management Council to facilitate the relationship between workers and management.

It wasn’t a big surprise, then, when a grown-up John went into industry himself. In 1980, Workman, then 33, became a partner in a year-old steel foundry called Eagle Alloy. A product of Muskegon’s robust metals industry, Eagle Alloy was created the previous year by workers at a larger foundry who saw their former employer waving off small orders for steel castings because the foundry was too busy. The workers saw the chance to supply the little guys. Eagle Alloy opened in a 3,000-foot pole barn with three employees and a $250,000 loan. Workman was optimistic. And, perhaps, naïve: 1980 — the year Jimmy Carter approved $1.5 billion in federal loan guarantees to bail out Chrysler — marked the beginning of a long twilight for American manufacturing. Over 30 years, the industry severely contracted, with the share of U.S. manufacturing jobs falling from 19.4 percent when Ronald Reagan came into office to less than 10 percent in 2010.

Mark Fazakeley, co-founder Eagle Alloy and Workman’s business partner, put it this way in a community newsletter published four years ago: 1979 was “probably the last really great year” for steel casting foundries.

“Back in the day, when people were working in foundries to support yourself going to college, manufacturing was pretty well recognized as worthy, high-paying work,” said Workman. “That’s changed. It’s disturbing to many of us.”

Their reasons for insourcing vary, but one theme is constant: It saves money. This is not a movement singularly based on ideology or patriotism, but on economic reality.

Muskegon’s story is familiar. Between the 1960s and 1990, about 18 million Americans were employed in manufacturing. More than a third of that workforce has vanished. The year of Eagle Alloy’s 30th anniversary, 2009, was its worst year, according to Workman. In the heat of the recession, work went down by 80 percent of the average at some points. “We all sacrificed,” said Workman.

But Eagle Alloy made it. In fact, it’s flourished. The scrappy company has a client base from all over the map — food processing, agriculture, mining, oil, gas, drilling, railroads. “Business is very good for us,” said Workman. “We’re running six days a week.” And Eagle Alloy is not the only Muskegon company doing well. With more than 16 percent of the city’s jobs in 2010 in manufacturing, the sector is twice as strong as the national average, according to the Brookings Institution.

“The city has seen a strong comeback in manufacturing,” said Mike Franzak, Muskegon’s assistant planner, in a recent interview. He cited the 423-acre Port City Industrial Park, home to companies that range from toolmakers to textiles. The bid to resurrect manufacturing was so successful, the city has the enviable problem of having more skilled jobs than skilled people to fill them. Electrical engineers are especially coveted. So are welders.

“Schools don’t produce skilled trade [workers] like they used to,” said Workman.

Workman and Cindy Larsen are among the agitators who see manufacturing as the future of cities, rather than the past. On the small scale, this movement is visible in tinkering culture, ignited by Maker Faires in cities around the country like Detroit, Urbana, Ill. and Columbus, Ohio. But it’s also going big, fueled by private and public policy that encourages companies to return outsourced jobs to American soil. In a word, insourcing.

The policy push is paying off. Over a period ending in August 2012, more than 530,000 manufacturing jobs were created — the greatest growth for any 30-month period since 1989. A motley crew of companies is responsible for the jump, including both experimental start-ups and the same industry titans that created factory towns during manufacturing’s 20th-century heyday. Their reasons for insourcing vary, but one theme is constant: It saves money. This is not a movement singularly based on ideology or patriotism, but on economic reality.

“Labor costs in Asia are ticking upward at a time that, for better or worse, American wages stay the same,” said Mark Muro, a senior fellow at the Brookings Institution. “And automation matters more and more, which reduces costs.”

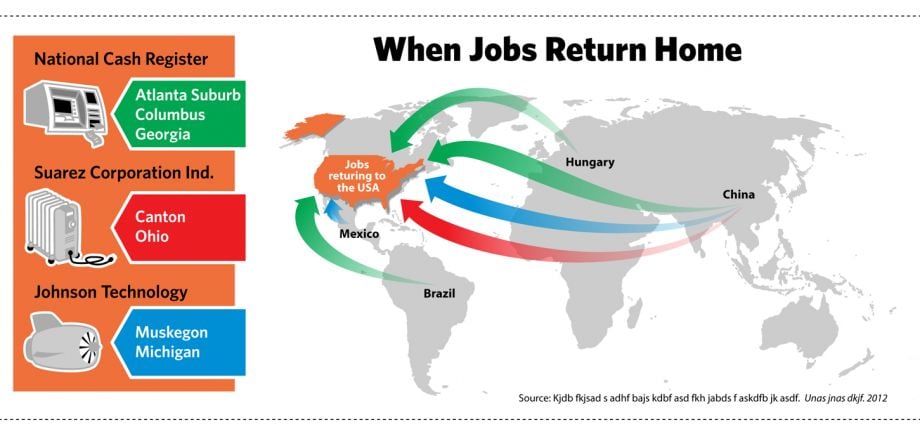

That trend is evident in Columbus, Ga., a city south of Atlanta that for decades watched as employers went out of business or left town. But in 2011, some momentum shifted when Columbus welcomed an ATM and self-service checkout machine manufacturer to town. The NCR Corporation made machines in China, Brazil and Hungary until its leaders realized that moving labor back to domestic shores saved on shipping costs that rise with the price of fuel (each ATM weighs about a ton). Intellectual property was another consideration — the company wanted workers near its engineers, narrowing the possibility for ideas to be leaked.

“We felt like controlling that innovation in-house was critically important,” said Peter Dorsman, NCR’s senior vice president of global operations. The company employs 500 at last count, and expects to hire 370 more by 2014.

“It’s computerized, technological, manufacturing jobs. And those jobs pay very well and make good livings for the families in our community,” Columbus Mayor Teresa Tomlinson told a local TV station last March, when the company opened its second plant.

Meanwhile, the Ford Motor Company has built the Fusion car in Mexico, but announced plans in September to hire 1,200 workers to make the 2013 car in metro Detroit. It’s a significant shift for a car that carries so much of the company’s fortunes with it — the Fusion is Ford’s best-selling vehicle after the F-150 truck. The motivation for the move? Changes in labor contracts passed in 2007 and 2011 had reduced costs. Not to be outdone, GM announced last October that it plans to insource 90 percent of its information technology work, with 1,500 jobs coming to Warren, Mich. in the next four years, and 500 more to Austin, Texas.

In Louisville, Ky., GE Appliances is building a new water heater plant in its massive Appliance Park facility. The new plant will be the first one there in half a century, and it — along with an existing plant that will start making refrigerators — is expected to generate hundreds of skilled manufacturing jobs. The $800 million investment is part of GE’s promise to reinvest in American workers, which has created 15,500 jobs since 2009, according to GE.

This insourcing revolution is significant for cities, particularly those mid-size urban centers in the Midwest that were forged in the fire of industry — those places like Muskegon. A recent report from Brookings Institution found that 80 percent of all manufacturing jobs and 95 percent of all high-tech manufacturing jobs are now in metropolitan regions, concentrated in the 100 largest metro areas. Because innovation is crucial in manufacturing, companies have an interest in locating near American universities, where engineers and designers can be tapped. The good news for the cities that attract industry is that manufacturing 2.0 jobs are safer and more environmentally conscious than in the past. The bad news is that new industry jobs do not necessarily pay as well as the old ones, particularly since the rise of insourcing hasn’t paralleled a rise in union membership and activity. And for the foreseeable future, despite the profoundly positive changes in 21st-century manufacturing, there simply aren’t enough jobs yet.

GE’s latest incarnation of Appliance Park, for example, employs a fraction of the number employed at the plant’s zenith. Campbell, Wyant & Cannon, the Muskegon foundry that employed John Workman’s father, celebrated its 100th anniversary in 2008 with less then 10 percent of the workforce it had at its peak.

This past November, voters got a reminder of how important manufacturing is to the American psyche. Both President Obama and challenger Mitt Romney portrayed their respective campaigns as the key to resurrecting the glory days of U.S. making. Obama championed the federal loans to GM and Chrysler as one of the great domestic successes of his first term. (The loans were initiated under former President Bush in 2008, but expanded under the Obama administration.) Today, both GM and Chrysler report record profits.

In March, Obama announced a major manufacturing platform under his “We Can’t Wait” initiative, putting $1 billion into a national network of up to 15 manufacturing innovation institutes around the country, each one cultivating its region as a hub of industry, manifesting what a future of making things in America looks like. The first opened its doors in Youngstown, Ohio this fall, bringing together a vast public-private partnership in Ohio, Pennsylvania and West Virginia to support additive manufacturing, or 3-D printing, for the Department of Defense.

“I’m pleased that we are taking steps to strengthen American manufacturing by launching a new manufacturing institute in Ohio,” Obama said in a news release for the center’s opening. “This institute will help make sure that the manufacturing jobs of tomorrow take root not in places like China or India, but right here in the United States of America. That’s how we’ll put more people back to work and build an economy that lasts.”

Meanwhile, Romney — a Michigan native whose father was president of American Motors — emphasized his campaign’s support of small private businesses and stressed the need to challenge China on unfair trade practices that hurt American manufacturers. Expanding on the theme, the Republican National Convention chose “We Built This!” as its slogan. Romney also ran a campaign ad in swing states proclaiming that under Obama, “we’ve lost over half a million manufacturing jobs.”

“For the first time China is beating us,” the ad darkly concluded.

For folks like John Workman, the attention on manufacturing is overdue.

“Washington is really beginning to understand that we need manufacturing to be competitive,” said Workman, “in way they didn’t 10 years ago when China was licking at their boots.”

Young workers are beginning to notice manufacturing, too. Not long ago, Byron Jenkins was working at a McDonald’s in Canton, Ohio, making minimum wage and trying to support his daughter. This summer, his life was transformed when got one of the first 100 jobs that Suarez Corporation Industries brought back from China. The company manufactures EdenPure space heaters and other small appliances, and Jenkins now works 40 hours a week as a floor hand in the factory and warehouse. “It’s fantastic,” he told a local business magazine. “Most jobs, you just sit there, work and go home. Here, I’m always on the move, always active… You’ve accomplished something once [the workday’s] over.”

It’s apparent that the greater Canton area straddles two worlds. It’s 60 miles south of Cleveland, but also on the edge of Amish country. It’s steeped in green lawns, brick homes and gracious churches. It describes itself as the cradle of American football: The Pro Football Hall of Fame is here, and high school games bring out the passion of a religious revival.

Proud of its tradition of “diversified industries,” as a former Canton city seal put it, the region was the birthplace of the Hoover Vacuum Company. But the onetime king of industry in North Canton moved nearly all its jobs to Mexico and El Paso, Texas in 2007, and the very last bit of local Hoover production — a tiny factory making vacuum bags and assembling an upright vacuum line — closed in 2012. Unexpectedly, in 2011 Suarez took over one of Hoover’s empty warehouses and brought it back to life. A tall pole with a billowing American flag now stands next to the Suarez sign. There’s a picnic table out back, where workers eat lunch.

Suarez brought 125 jobs from China into central Ohio when it opened in the Hoover warehouse. Another 300 more are anticipated. While sentiment was involved — CEO Ben Suarez is a native of the area — it also made business sense. “Most companies don’t want to manufacture in Asia,” Suarez told the Cleveland Plain Dealer. “They have to because companies want to produce products at a price that customers are willing to pay.” But again, the long waiting periods, and high shipping expenses to move products from Asia to the U.S., countered the advantage of lower labor costs in China — especially as wages and benefits in China are rising. Suarez told the Plain-Dealer that long wait times on shipping caused him to lose business.

After three years of study, Suarez decided that costs should about even out at the North Canton factory. Rising sales — the company has a distribution deal with Lowe’s, the home improvement store, and its in-house research demonstrated a 30 percent increase in interest when products have a “Made in the USA” label — should tip the advantage toward insourcing. (While the company receives no state or federal tax breaks, North Canton will refund the company up to half of city income taxes paid by employees for the first two years of operation here.)

Doug Lane is president of the North Canton Area Chamber of Commerce, and a former city councilmember. While the city’s teenagers still attend a high school bearing the Hoover name, Lane remembers counting down the days before the legendary company left the Ohio town where it was built and moved the last of its jobs thousands of miles away. Years before the doors closed for the last time, the city adjusted its budget in anticipation of the loss of taxes.

But there’s been a “rebirth of the property over there,” said Lane, with Suarez leading the way and nine other companies — light manufacturing, service, administration — using other parcels of the former Hoover warehouse. This isn’t the noisy, large-scale manufacturing of the past. As Lane describes it, “on one side of the wall, someone’s building electric transformers, and on the other side of the wall, somebody’s sitting quietly doing computer work.” Lane’s glad to see the diversity. “We don’t want to put all our eggs in one basket again,” he said.

Lane is aware that the city is “not out of the woods yet,” but, he said, “anyone would give their right arm to have over 1,000 jobs in a factory that was empty three years ago.”

“On one side of the wall, someone’s building electric transformers, and on the other side of the wall, somebody’s sitting quietly doing computer work.”

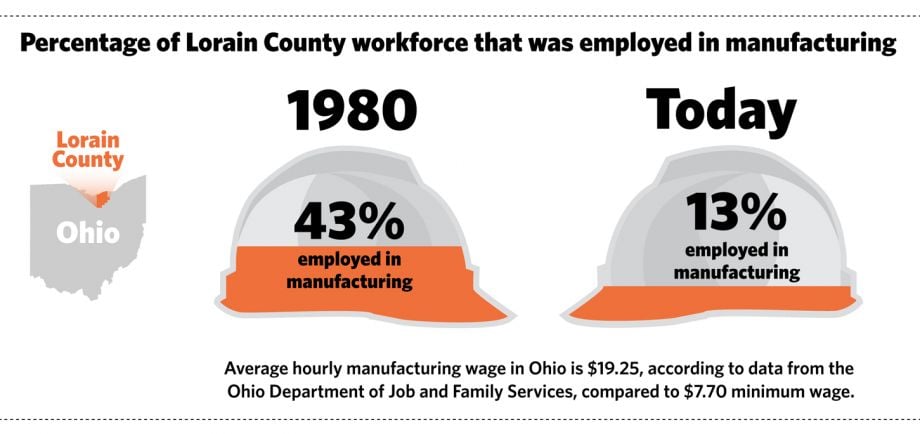

A knee-shakingly large line of applicants applied for Suarez’s first job openings. And that was for jobs that start at minimum wage — boosted to $7.85 in 2013 — and end at $14, compared to the $13-$20 per hour made by Hoover employees. Despite the demand for Suarez jobs, the new plant’s wages are well below the average hourly manufacturing wage in Ohio ($19.25 in 2011, according to data from the Ohio Department of Job and Family Services).

And, of course, Suarez employs exponentially fewer jobs than Hoover did: There were still about 4,000 Hoover employees in North Canton in the late 1980s. But for those who didn’t get the nod at Suarez, they might take hope from the fact that Ben Suarez didn’t sign the lease until he’d picked out about 11 acres of land he could use for expansions. Someday, he told a reporter, not too long from now, he might be employing thousands.

Whether it’s insourcing or creating new manufacturing jobs, many cities are taking aggressive steps to reestablish industry.

“More and more manufacturing, especially advanced manufacturing, is in the United States,” said Muro, from the Brookings Institution. “The broad trends are well documented now. Massive job losses accelerated in this decade, but we’re coming out of crisis and having this mini-boom, with, statistically, production going up, job losses ceasing.”

In Lorain County, Ohio, 43 percent of all working adults were employed in manufacturing in 1980. Today, it’s 13 percent. “But,” Dr. Roy Church hastened to add, “the value of manufacturing today is about the same as it was in 1980. We’re producing as much with less workforce.”

Nobody is better acquainted with the ambivalence of that reality than Church. He’s been president of Lorain County Community College in northeast Ohio since 1987, and has all but presided over the region’s revolutionary economic shift. How do you educate a community for diminishing jobs? What’s the point of learning a vocation if there’s no vocation to be had?

I spoke with Church in the Entrepreneurship Innovation Center on the community college’s south campus. The bright building opened five years ago, but still has the astringent smell of newness. Its rooms have ambitiously entrepreneurial names, like “Flex Training Lab A.” In this hopeful space, Church rattles off deadening statistics. During the recession in the 1980s, 80 local companies closed in three years. Lorain County’s unemployment hit 25 percent. Elyria, the county seat, is home to 54,000 people, more than 16 percent of whom live below the poverty line. By the time Church took the helm of the community college in 1987, he said, the community was looking to us “to right the ship. How can we use the college to raise industry?”

Nearly all U.S. cities and counties subsidize job creation. Where Lorain County distinguishes itself is in methodology: Instead of simply giving companies tax breaks or land, the city provides tools — literally, the tools — that companies need to grow in a changing marketplace. Lorain County amplifies limited resources, and is aggressively reinventing itself in a way that lives up to the best of the manufacturing spirit: Making useful things from scratch.

Through tactics both practical and philosophical, Lorain County has become a model for other cities and counties trying to cultivate manufacturing.

For starters, the community college created a resource center that’s open to businesses. Called the Entrepreneurship Innovation Center, the facility offers access to a clean room and fabrication laboratory, or “Fab Lab,” where entrepreneurs use the school’s industrial technology and digital tools. “Businesses come in at night and on weekends to create with equipment they couldn’t afford to invest in,” Church said.

Jonathan Katz is chief operating officer of Pressco, a company that manufactures food and beverage containers in Elyria. Using the “Fab Lab,” Pressco stumbled upon a technology breakthrough, he said. Reticent to share much, Katz described the breakthrough as an “extremely energy efficient technology” that will “hopefully replace every microwave.” He led the commercialization of it — he’s starting by targeting fast food companies — and will open a factory early this year to fill orders. Katz said the community college equipment made it possible for his company to design its manufacturing process before it could invest in equipment of its own. And because the company trains students to use equipment identical to what Pressco uses, and understand the science behind it, Katz has a skilled workforce on hand.

In partnership with county commissioners and the Ohio Department of Development, the college also created a business incubator that provides entrepreneurs with start-up capital. LCCC calculates that since its founding in 2001, it has supported 105 companies, 94 of which are still succeeding, creating 700 jobs with an average salary of $48,000 — about average for the county. Incubated companies range from Cleveland Whiskey to Anderson Aerospace.

These ventures into private enterprise ultimately led LCCC to notice voids in modern industry that the college could fill. Enter the Lorain sensor lab.

Sensor technology, Church noticed, is an enormous growth sector that’s “very powerful and very niche; everybody wants to get access to these tools. Everybody wants everything to be ‘smart.’”

Tracy Green, director of advancement at the college’s foundation, investigated how sensor technology becomes a product and learned that not much gets out of the labs and into industry. Green and her team figured LCCC could help with sensor commercialization. It received $5.5 million from Cleveland State University for high-level equipment and operations, providing tools for companies to test products with sensor components — how they handle harsh environments, for example. It’s an educational program, not a business, but it has a palpable economic impact. Companies like RW Beckett and Greenfield Solar rely on the college for manufacturing support.

“[LCCC] has a lot of new equipment that would be prohibitive for us to purchase separately,” said John Bohan, vice president at Beckett, which makes oil burners and, increasingly, electronics with sensors.

Call this onshored outsourcing. The work happens outside company walls — but inside the U.S.

The community college’s expertise in sensor commercialization made it an obvious partner in the $70 million National Additive Manufacturing Innovation Institution, Obama’s “We Can’t Wait” center that’s part of the federal push for U.S. manufacturing. NAMII is the pilot project, and brings together 40 companies, 14 universities and community colleges, and 11 non-profits in Ohio, Pennsylvania and West Virginia.

But Church and Green are under no illusions that the future of manufacturing in Lorain County will look like what it did 60 years ago. And in some ways, this is a good thing. New industry won’t create as many jobs as there once were, but many skilled jobs are higher paying and serve as multipliers of local prosperity. Those jobs are safer and more environmentally attuned than in the past. There are fewer pluming smokestacks and more safety precautions: Green said that these days, manufacturing “looks like an operating room… it is manufacturing, but it’s done at a nano level.” Church agreed: “It’s a very sophisticated environment, very different than the historical images of manufacturing in northeast Ohio.”

Gary Fedder echoed this idea. He’s a leader in the NAMII project and heads the Institute for Complex Engineered Systems at Carnegie Mellon University. Fedder tidily listed the most common misconceptions of modern manufacturing as “The three D’s: Dirty, dangerous, dull.”

“When you say manufacturing, you think of an auto assembly line or a sweatshop in China,” Fedder said. “There’s a lot of automation, of course, but that doesn’t mean that there are not jobs. It’s just different kinds of jobs. And with automation, that means those jobs are not as dangerous, more exciting and less repetitive.”

Another transformation for Lorain County manufacturing? The presence of women. Green said today’s industry “opens up opportunities in half of the talent pool that wasn’t present in the past. I think today you’ll see an equal balance.” There simply aren’t the same systemic barriers to keep women from the work of making things.

But as manufacturing wheels into the 21st century, another sort of worker may be left out. Those without higher education or specialized training could more easily enter the factory of the past than the Fab Lab of today.

This is the case at Johnson Technology in Muskegon. Two years ago, when the state was licking its recession wounds, GE announced it would bring 1,100-1,300 new jobs — making aircraft engines and parts — to its Muskegon aviation factory. Many of those jobs were previously performed in Mexico and China. Today, they’re in the unassuming Johnson Technology facility in Muskegon’s Port City Industrial Park.

It was windfall for a city with a median household income of about $26,000. At one point, GE declared that it was “now hiring technical talent at the rate of two per day in the state — with over 90 percent of the first 200 new hires coming from Michigan.” But Muskegon residents were less than 11 percent of hires. Michelle Messer, financial analyst for Johnson Technology, described the new jobs to the city commission as being mostly machinists, manufacturing technicians and machine operators. The company needed employees with experience: “These are not basic entry-level jobs,” she said, according to Mlive, a statewide news site.

But as manufacturing wheels into the 21st century, another sort of worker may be left out.

Today’s manufacturers can be choosier than those that fed and clothed much of the 20th century’s middle class. This puts pressure on places like community colleges and chambers of commerce to train an emerging workforce. But it’s not easy to convincingly promote a new generation of manufacturing jobs to disillusioned workers of any age, nor is it simple to understand the roles and skills needed in new industry. But the payoff is clear.

Last fall, NAMII opened its storefront on Boardman Street in Youngstown, Ohio, a former locus of the steel industry. The hub capitalizes on local expertise in additive manufacturing, or 3-D printing. This is a process where a digital model is used to make real-world products. A worker puts thin layers of real material, one on top of the other, following the instructions in a digital file. It’s not long before the product is ready for use. Many expect 3-D printing to transform the manufacturing of just about everything: Furniture, cartridges, guns, shoes.

LCCC’s sensor specialty is useful for both the NAMII machines themselves and the products those machines build. For those in Lorain County, opportunity looms. Staying late on a recent Friday evening, Green and Church were holed up in the Entrepreneurship Innovation Center, neither of them so much as blinking at the darkened sky that was getting darker. Green was describing the Lorain County jobs and clever products that this work could lead to. “We’re so excited about this!” she exclaimed, holding up a chart. “I think you can tell we’re excited about this!”

Our features are made possible with generous support from The Ford Foundation.

Anna Clark is a journalist in Detroit. Her writing has appeared in Elle Magazine, the New York Times, Politico, the Columbia Journalism Review, Next City and other publications. Anna edited A Detroit Anthology, a Michigan Notable Book. She has been a Fulbright fellow in Nairobi, Kenya and a Knight-Wallace journalism fellow at the University of Michigan. She is also the author of THE POISONED CITY: Flint’s Water and the American Urban Tragedy, published by Metropolitan Books in 2018.

Follow Anna .(JavaScript must be enabled to view this email address)

Alex Lukas was born in Boston in 1981 and raised in nearby Cambridge. With a wide range of artistic influences, Lukas creates both highly detailed drawings and intricate Xeroxed ‘zines. His drawings have been exhibited in New York, Boston, Philadelphia, Los Angeles, San Francisco, London, Stockholm and Copenhagen as well as in the pages of Megawords, Swindle Quarterly, Proximity Magazine, The San Francisco Chronicle, The Village Voice, Philadelphia Weekly, Dwell, Juxtapoz, The Boston Globe, The Boston Phoenix, Art New England and The New York Times Book Review. Lukas’ imprint, Cantab Publishing, has released over 35 small books and ‘zines since its inception in 2001. He has lectured at The Maryland Institute College of Art, The University of Kansas and The Rhode Island School of Design. Lukas recently partnered with the The Borowsky Center at The University of the Arts in Philadelphia to produce an eight-color offset lithograph as part of the 2011 Philagrafika Invitational Portfolio. His work was also recently acquired by the West Collection as part of the 2011 West Prize. Steven Zevitas Gallery presented an exhibition of new works on paper this spring. Lukas is a graduate of the Rhode Island School of Design and now lives and works in Philadelphia.

20th Anniversary Solutions of the Year magazine