The big obstacle to getting public buy-in on rail transit is the fact that the public will be paying for it for as long as it runs. Only in the densely packed cities of Japan, Singapore and Hong Kong do rail mass transit systems turn a profit on operations, and of those, only one — Hong Kong’s Mass Transit Railway (MTR) — makes a profit large enough to cover the entire cost of capital improvements and extensions. That’s due in part to Hong Kong’s high population density, in part to its low rate of car ownership (a function of that density), and in part because the MTR also makes money as a landlord of properties around its stations.

Few Americans would want to live at Hong Kong, Singapore or Tokyo densities, so the Hong Kong approach to profitable rail transit is out of reach in the United States, even if “value capture” were to become more widespread. But there is someone out there who has been hard at work coming up with a rail transit technology that can pay for itself, even in an American context.

Kirston Henderson, an engineer in Fort Worth, Texas, is the founder and CEO of ROAM Transport Systems, a company that has developed a modular fixed-guideway transit system. Henderson says it can be built with minimal public funds and can cover its own operating and maintenance costs out of fare revenues.

The system, which comes in small-, medium- and large-capacity versions, is an elevated rail transit system he developed in order to solve two problems he saw in transporting goods and people: the high cost of building urban freeways and the higher cost of building urban rail.

By his own description, Henderson is an inveterate tinkerer, a product of his education and career choice.

“I have a master of science in physics, which makes you a jack of all trades in the engineering field,” he says. In systems engineering, that means “you take a problem and figure out a better way to solve it.” He also holds 15 patents representing some 100 unique claims, the fruit of all that tinkering.

“One of the things I decided I needed to take apart and find a better answer for was the issue of surface transportation, both rail and bus.”

The problem, as he saw it, was that both fast highways and fast trains were too costly and inefficient. Much of the cost of a freeway goes into laying down concrete that tires will almost never actually touch, while rail transit systems all require subsidies to build and run.

“I analyzed the problem and came up with a number of requirements. It had to be able to climb hills in all weather” — something no steel-wheel technology can do. “It needed to move cargo, to provide point-to-point transportation for people in their individual cars, and it needed to provide both local transportation and high-speed intercity transportation.

“The other problem was that it had to be affordable” — less than the cost not only of a mile of light rail or subway, but also the cost of a mile of urban freeway.

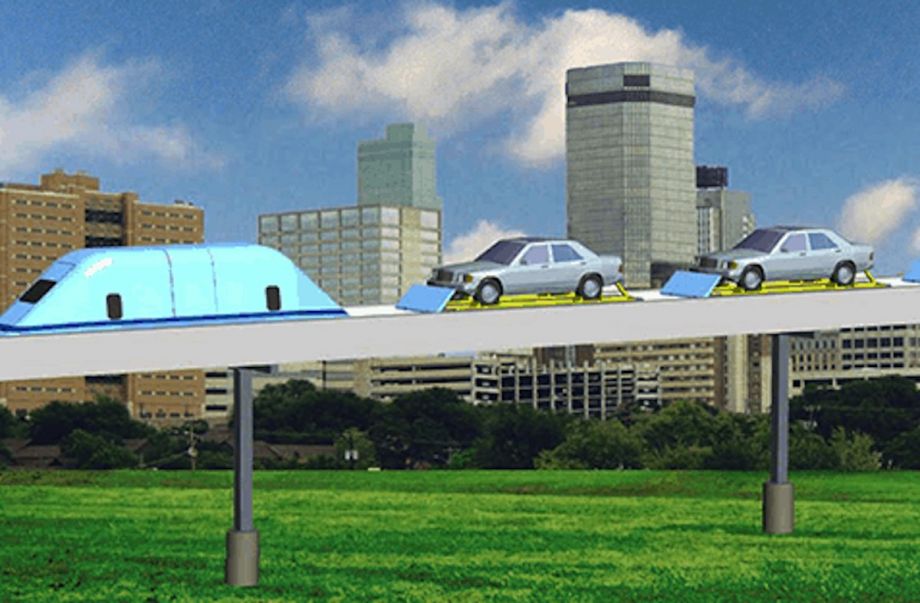

The solution he developed is a cousin of the rubber-tired metro technology developed in France and found on subways in Paris, Mexico City and Montreal. The difference is that Henderson’s system is essentially two one-tire-wide highways enclosed in box culverts. The rubber-tired modular cars touch only the metal strips in the bottom of the culvert, which also contains the power supply and guidance system. The “tracks” are mounted on support pillars to form an elevated rail line.

The vehicles carry either passengers, goods or cars that would drive onto flatcar platforms and would operate automatically, with no drivers. Henderson envisions them operating autonomously rather than in trains.

Henderson claims that his “MegaWay” system, designed for urban transit applications, costs 20 to 25 percent of a light-rail line.

“The cost of the guideway, the power supply system and the initial complement of vehicles is about $10 million per mile,” a figure he arrived at based on bids he submitted to some urban transit agencies. By comparison, a lane mile of Interstate highway costs $16 million and a typical light-rail or intercity high-speed rail line costs around $100 million a mile.

“We want to price this system in a range where cities can build it with their own money.”

So far, there have been no takers, but testing of the system continues at the company’s facility in Texas.

Next City contributor Sandy Smith is the home and real estate editor at Philadelphia magazine. Over the years, his work has appeared in Hidden City Philadelphia, the Philadelphia Inquirer and other local and regional publications. His interest in cities stretches back to his youth in Kansas City, and his career in journalism and media relations extends back that far as well.

Follow Sandy .(JavaScript must be enabled to view this email address)

_600_350_80_s_c1.jpg)